Dagelijks worden we omringd met kunststof producten; in onze auto, onze kleding, huishoudelijke apparatuur en allerhande gebruiksvoorwerpen, je vindt het overal. En natuurlijk worden plastics ook gebruikt in veel verpakkingen voor eenmalig gebruik en helaas vinden we dat ook in toenemende mate, door verbranding en zwerfvuil, terug in ons milieu. Het maakt ons leven alleen aangenamer mits het na gebruik niet wordt verbrand of weggegooid, maar juist wordt hergebruikt. Gelukkig zijn we, zowel consumenten en bedrijven, ons steeds meer bewust van de noodzaak van het circulair gebruik van plastic.

De Veolia vestiging in Vroomshoop is al sinds 1969 actief op het gebied van kunststofrecycling. Onze focus ligt hierbij op de ontwikkeling, productie en verkoop van hoogwaardige compounds gebaseerd op gerecycled polypropyleen (rPP), een moderne en veelzijdige kunststof. De kwaliteit van deze rPP is net zo goed als virgin plastic en daarmee een echt duurzaam alternatief, dat helpt om de carbon footprint te verlagen. Onze ervaring maakt ons toonaangevend op het gebied van het hergebruiken van kunstof en is het ‘Centre of Excellence’ van Veolia Wereldwijd.

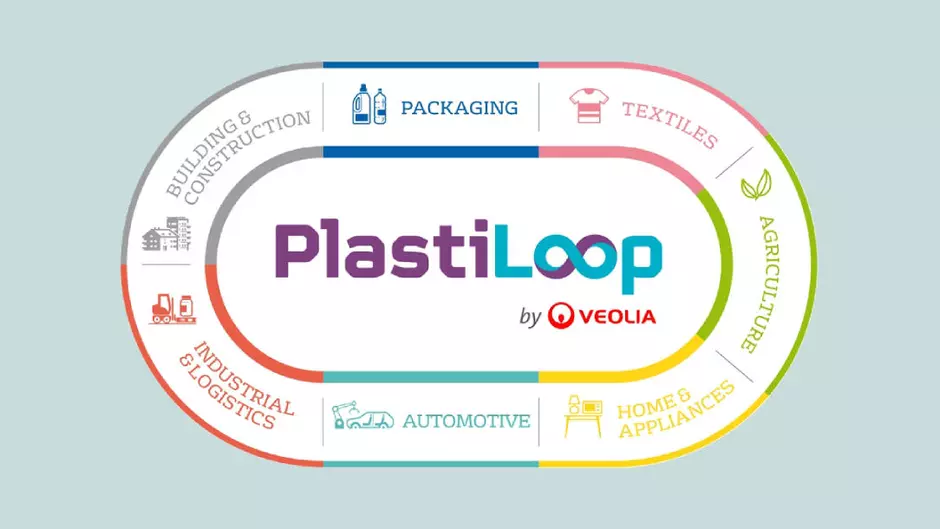

PlastiLoop

Het gerecycled polypropyleen (rPP) van Veolia Nederland maakt deel uit van het wereldwijde aanbod van Veolia met PlastiLoop. Dankzij ons wereldwijde netwerk van deskundigen en jarenlange ervaring, biedt PlastiLoop een uniek assortiment van granulaten dat geschikt is voor diverse toepassingen. Wereldwijd maar lokaal, richten wij ons op zeven industrieën om een circulaire economie van plastics te bevorderen.

Ons productengamma is het meest complete aanbod van circulaire polymeren ter wereld. Uiteraard blijft het groeien met onze ontwikkelingen en de evolutie van uw behoeften.

Van afval naar grondstof

Om tot een goed compound te komen is een constante kwaliteit van het maalgoed van het gerecyclede kunststof van belang. Veolia-onderneming Aufderhaar Kunststof Recycling maalt en wast PP of HDPE afval tot een schoon maalgoed.

De basis hiervoor ligt in PP- en HDPE-gesorteerde balen uit consumentenverpakkingen of verpakkingen uit de land- en tuinbouw. Door te investeren in de kwaliteit van de was- en maalstraat kunnen naast productie-uitval ook consumentenverpakkingen verwerkt worden. Hierbij richten we ons op de aankoop van gesorteerd balen kunststofafval (PP en HDPE) uit zowel de voor- als na-sortering.

De modern ingerichte productieomgeving, bestaande uit 4 speciaal gebouwde waslijnen is geschikt voor het vóór-shredderen, wassen, en malen van recyclebare kunststofafval tot een hoogwaardige grondstof voor verdere verwerking in de recycle-industrie.

Het PP en HDPE maalgoed dat we leveren, zowel binnen Nederland als in Europa, is van een constante kwaliteit. Daarnaast kunnen we ook afwijkende kwaliteiten maalgoed aanbieden en zijn we in staat om loonwerkopdrachten aan te nemen.

Benieuwd naar wat we voor u kunnen betekenen? Neem dan contact met ons op. We vertellen u graag over de mogelijkheden.

Afval bestaat niet! Recycling van plastics is een krachtig middel om circulariteit in de hele waardeketen te stimuleren.

Constante kwaliteit en beschikbaarheid dankzij grip op grondstoffen

Voor de beste kwaliteit rPP Compound is het cruciaal om grip te hebben afvalstroom met grondstoffen. Dat betekent niet alleen kennis hebben van de grondstoffen zelf, maar ook van de markten waarop zij verkrijgbaar zijn.

Met heldere inkoopspecificaties voor grondstoffen bepalen we mede de kwaliteit van het uiteindelijke recyclaat. Een strenge controle op eigenschappen en samenstelling, getest en gemeten volgens internationale normen, is voor ons de dagelijkse praktijk. Door onze toeleveranciers nauw te betrekken bij onze productieprocessen zorgen we voor continue kwaliteit en volumes.

Gerecyclede polypropyleen gebaseerd op twee soorten grondstoffen:

- Post-consumer grondstoffen afkomstig uit (voedsel) verpakkingen

- Post-consumer grondstoffen afkomstig van diverse consumenten artikelen (huishoudelijke artikelen, tuinmeubels, etc.)

Het mengen van beide soorten biedt ons de mogelijkheid rPP compounds te maken, met een breed scala aan eigenschappen. Op deze manier kunnen wij snel en effectief inspelen op vragen en behoeften voor de diverse toepassingen.

Uit consumenten afval (bijvoorbeeld voedselverpakkingen of flacons) recyclet Veolia op een duurzame manier jaarlijks meer dan 45.000 ton polypropyleen in Nederland.

Hoe we het maken

Ons aanbod bestaat uit een uitgebreid en in eigen huis ontwikkeld assortiment PP-compounds aan. Ook klantspecifieke ontwikkelingen behoren tot de mogelijkheden. Onze R&D afdeling vertaalt al uw wensen in een optimale PP-compound specifiek voor uw productieproces. De eigenschappen kunnen eenvoudig worden aangepast voor een tweede, derde of zelfs vierde leven. Dat kan een zelfde of een geheel andere toepassing zijn. Met slim hergebruik behouden we de waarde van PP.

Onze productie begint met een 100% controle bij de aangevoerde grondstoffen. Het is getest op de belangrijkste eigenschappen dat moet voldoen aan onze kwaliteitseisen. Eenmaal vrijgegeven worden de diverse grondstoffen vervolgens in specifieke samenstellingen gemengd en verwerkt tot de compound. Tijdens dit proces wordt het materiaal gesmolten en gehomogeniseerd. Verschillende slimme additieven zorgen er voor dat het materiaal voldoet aan uw gewenste specificaties. Denk hierbij aan kleur, viscositeit, stijfheid, slagvastheid etc. De zorgvuldig voorbereide grondstofmix wordt uiteindelijk gesmolten en gehomoniseerd. Tijdens dit proces worden eventueel nog aanwezige stoorstoffen als metaal, papier, PET en vocht verwijdert en tegelijkertijd worden eventueel gewenste additieven toegevoegd.

De uiteindelijke vrijgaveprocedure loopt via ons eigen laboratorium . Een strenge eindcontrole bepaalt of aan de uw specificatie wordt voldaan. Na goedkeuring wordt het materiaal voorzien van een analysecertificaat en aan u geleverd.

Kwaliteitscontrole

Bij Veolia beschikken we over de modernste analysetechnieken om onze recyclaten te karakteriseren. Kwalitatieve methodes, als DSC, IR en XRF, stellen ons in staat de samenstelling te bepalen en eventuele vervuilingen te traceren. Het bepalen van de belangrijkste mechanische eigenschappen, zoals stijfheid, slagvastheid en verwerkingseigenschappen als meltindex, gebeurt conform internationale test normen.

Gecertificeerde kwaliteit

Omdat we niet alleen op onze ervaring vertrouwen, zorgen we dat alle processen zijn beschreven, we deze continu bewaken en daar waar mogelijk direct verbeteren. Het Eucertplast certificaat biedt u de extra zekerheid dat onze producten, en dus uw grondstof, duurzaam tot stand is gekomen.

Met het gebruik van gerecycled plastic maken we uw producten circulair en verlagen we uw CO2-voetafdruk.

In vele kleuren en smaken

Ons productassortiment bestaat uit een aantal standaard grades, speciaal ontwikkeld voor toepassing in spuitgieten en thermovormen.

De tijd dat gerecycled plastic alleen maar in zwart verkrijgbaar was ligt inmiddels ver achter ons. Door kleursortering, voorscheiding van grondstoffen en in huis ontwikkelde inkleuringstechnieken is een breed kleurenpallet mogelijk. Hierdoor kan ons recyclaat nieuw materiaal vervangen. Dit verlaagt uw kostprijs terwijl uw product gelijktijdig duurzamer wordt.

Toepassing

Op basis van bijzondere eisen en wensen ontwikkelen we ook klantspecifieke recyclaten. Deze zijn exact afgestemd op de unieke productspecificaties en productieprocessen van onze klanten. Of het nu gaat om auto onderdelen die tegen een stootje moeten kunnen, transportkratten, weerbestendige tuinmeubelen of een verpakking voor verf of vaatwastabletten, je komt ons inmiddels overal tegen.

Assortimentsoverzicht

Door een groeiend aantal toepassingsmogelijkheden is onze R&D-afdeling dagelijks bezig nieuwe recyclaten te ontwikkelen. Zoekt u een recyclaat in een bepaalde kleur of met andere specifieke eigenschappen? Neem dan contact met ons op. We vertellen u graag over de mogelijkheden.

Verwerking van uw eigen uitval

Wilt u uw eigen uitval opwaarderen voor hergebruik, of heeft u behoefte om op basis van uw eigen receptuur compounds te laten vervaardigen? Onze expertise en machines staan u ter beschikking, niet alleen voor PP, maar ook voor de meeste andere kunststoffen. Benieuwd naar wat we voor u kunnen betekenen? Neem dan contact met ons op. We vertellen u graag over de mogelijkheden.

Door de oneindige mogelijkheden van gerecyclede plastics verwacht de consument dat iedere fabrikant maximaal inzet op de toepassing hiervan.

Op weg naar een betere toekomst

We leven op een planeet waar we niet goed voor gezorgd hebben. En daar betalen we nu de prijs voor. Nooit eerder waren milieuproblemen zo direct zichtbaar, of de gevolgen ervan voor onze samenleving zo reëel. Door het benchmarkbedrijf voor ecologische transformatie te worden, werkt Veolia aan de toepassing van bestaande oplossingen te versnellen en uit te breiden en tegelijkertijd de oplossingen van morgen te creëren.

Dit doen we hand in hand met onze klanten, in de overtuiging dat economische, sociale en milieu-uitdagingen een probleem voor ons allemaal is. Met onze kunststofrecycling dragen we bij aan de aanpak van vier grote uitdagingen.

Bestrijding van

klimaatverandering

Vervuiling tegengaan

Optimaliseren van

grondstoffen

Kwaliteit van leven

verbeteren

Ons ecosysteem om samen aan een betere toekomst te bouwen

Met de publieke opinie en regelgeving in het achterhoofd vinden merken en klanten hun productie- en consumptiegewoonten grondig opnieuw uit. Door gebruik te maken van onze polymeren draagt u sterk bij aan:

- Het verminderen van het gebruik van nieuw plastic

- Het verbruik van natuurlijke hulpbronnen te verminderen

- De uitstoot van CO2 te verminderen

Dit alles natuurlijk zonder de kwaliteit van uw producten in gevaar te brengen.

Zo vermindert u met het gebruik van circulaire kunststoffen, als vervanging van nieuwe kunststoffen, de CO2-uitstoot met meer dan 70%, het waterverbruik met meer dan 80% en maakt u een enorme impact op de verlaging van het gebruik van grondstoffen. Het is ook een krachtig middel om circulariteit in de hele waardeketen te stimuleren, inclusief initiatieven voor duurzame inzameling op grote schaal.

Samenwerkingen

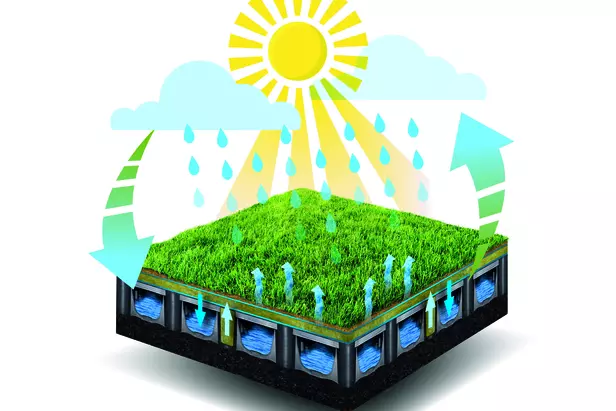

Het innovatieve TKI Project CitySports dat zich in dit pilotproject richt op stedelijke koelingsoplossingen, circulair gebruik van (afval)materiaal, opvangen en gebruik van regenwater en veilig sporten op kunstgrasvelden. Veolia heeft hiervoor de kunststof voor de Permavoid sportfundering onder het veld geleverd. Deze cassettes, waar het water wordt opgevangen, zijn volledig circulair. De kunststof is 100% gerecycled uit afval dat iedereen dagelijks weggooit.

Om de kwaliteit van de verfemmers te garanderen is er uitgebreid getest; emmers werden bijvoorbeeld gevuld met water en zand, gestapeld, vervoerd en gelost. De samenstelling van het granulaat voldoet aan alle eisen. Hiermee bewijzen de bedrijven dat de perfecte verfemmer gemaakt kan worden uit consumentenafval.

Hiervoor werd onder andere de nieuwe verpakking voor de Finish Quantum vaatwastabletten ontwikkeld. Het gebruik van gerecycled polypropyleen was een uitdaging, vanwege de kleur en de geur. Dankzij het doorzettingsvermogen van beide partijen is een klantspecifieke compound gemaakt, dat voldoet aan de strenge esthetische en technische eisen voor deze verpakking.